What Makes XLFMKK Cable the Right Choice for Low Voltage Marine Power Systems?

Discover why XLFMKK cables are the preferred solution for marine power systems. Learn about their LSZH properties, fire safety compliance, EMC shielding, and superior environmental resistance for shipboard and offshore applications.

BLOGS

6/20/202514 min read

Introduction: The Demands of Modern Marine Power Systems

The maritime industry has witnessed unprecedented growth in the complexity and sophistication of shipboard and offshore electrical systems over the past decades. Modern vessels, from commercial cargo ships to luxury cruise liners, and offshore installations, from drilling platforms to floating production facilities, now depend on intricate networks of electrical power distribution systems that must operate reliably under some of the harshest conditions on Earth.

These advanced marine electrical systems present unique challenges that extend far beyond those encountered in terrestrial applications. The combination of saltwater exposure, extreme temperature variations, constant vibration, mechanical stress from wave action, and the confined nature of shipboard spaces creates an environment where cable selection becomes absolutely critical to both operational safety and system reliability.

The stakes for proper cable selection in marine environments cannot be overstated. A cable failure at sea can result in loss of critical systems, putting lives at risk and potentially leading to environmental disasters. Furthermore, the enclosed nature of shipboard spaces means that any fire or toxic gas emission from electrical cables can quickly become life-threatening for crew and passengers alike.

This demanding operational context has led to the development of specialized marine cables that must meet stringent international safety standards while delivering exceptional performance under extreme conditions. Among these specialized solutions, XLFMKK cable stands out as a particularly well-engineered choice for low-voltage marine power systems, combining advanced materials science with proven construction techniques to deliver uncompromising safety and reliability.

XLFMKK represents a sophisticated approach to marine cable design, incorporating Low Smoke Zero Halogen (LSZH) technology with cross-linked polyethylene insulation and comprehensive electromagnetic compatibility protection. This combination addresses the three fundamental requirements of marine electrical installations: fire safety, environmental durability, and electromagnetic integrity.

Understanding XLFMKK Cable Construction

To fully appreciate why XLFMKK cables excel in marine applications, we must first examine the sophisticated engineering behind their construction. The designation "XLFMKK" is not merely a product code but rather a systematic description of the cable's layered construction, with each letter representing a specific functional component designed to address particular challenges in marine environments.

The foundation of XLFMKK cable performance begins with the "X," which designates cross-linked polyethylene (XLPE) insulation. Cross-linking represents a fundamental advancement in polymer chemistry where the polyethylene molecules are chemically bonded together in a three-dimensional network structure. This process transforms the thermoplastic polyethylene into a thermoset material with dramatically improved properties.

The cross-linking process creates molecular bridges between polymer chains, resulting in insulation that maintains its structural integrity even when subjected to elevated temperatures that would cause conventional thermoplastic insulation to soften or deform. This enhanced thermal stability proves particularly valuable in marine applications where cables may be exposed to engine room heat, direct sunlight on deck installations, or the elevated temperatures that occur during short-circuit conditions.

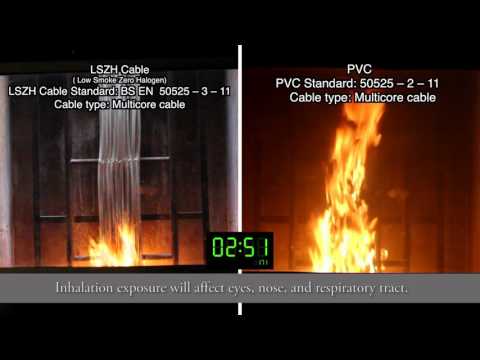

The "L" designation indicates the cable's Low Smoke Zero Halogen (LSZH) sheath construction, which represents perhaps the most critical safety feature for enclosed marine environments. Traditional cable sheaths often contain halogenated compounds, particularly polyvinyl chloride (PVC), which release toxic and corrosive gases when exposed to fire. In the confined spaces typical of shipboard installations, these toxic emissions can quickly reach lethal concentrations.

LSZH materials, by contrast, are formulated from halogen-free compounds that produce minimal smoke and non-toxic gases when subjected to fire conditions. This characteristic proves absolutely essential in marine applications where evacuation routes may be limited and ventilation systems may be compromised during emergency conditions.

The "F" designation highlights the cable's flame retardant properties, which work in conjunction with the LSZH sheath to provide comprehensive fire protection. These flame retardant characteristics are not merely additive compounds but are engineered into the material structure to provide self-extinguishing properties while maintaining the cable's mechanical and electrical performance characteristics.

The first "M" in the designation refers to the metallic screening layer, typically constructed from copper wire braid or aluminum foil tape, which provides electromagnetic compatibility (EMC) protection. Modern marine vessels contain sophisticated electronic navigation, communication, and control systems that can be susceptible to electromagnetic interference. The metallic screen serves as a Faraday cage around the power conductors, preventing both the emission of electromagnetic energy from the cable and the ingress of external electromagnetic interference.

The dual "K" designations represent the inner and outer thermoplastic halogen-free sheaths that provide additional mechanical protection and environmental sealing. This multi-layer approach ensures that even if the outer sheath is damaged during installation or service, the inner protective layers maintain the cable's integrity and safety characteristics.

XLFMKK cables are typically rated for 0.6/1 kV operation, making them suitable for the low-voltage distribution systems commonly found in marine applications. The voltage rating indicates that the cable can safely operate with a conductor-to-earth voltage of 600 volts and a conductor-to-conductor voltage of 1000 volts, providing adequate safety margins for typical shipboard power distribution voltages.

The operating temperature range of XLFMKK cables extends from -40°C to +90°C for continuous operation, with short-circuit tolerance allowing conductor temperatures up to +250°C for brief periods. This wide temperature range ensures reliable operation in everything from Arctic shipping routes to tropical offshore installations, while the short-circuit tolerance provides additional safety margins during fault conditions.

Certified Safety and Fire Performance

The marine environment presents unique fire safety challenges that have driven the development of comprehensive international standards specifically addressing cable performance in shipboard and offshore applications. XLFMKK cables have been rigorously tested and certified to meet these demanding requirements, providing marine engineers with documented assurance of their safety performance.

The foundation of marine cable fire safety standards rests on the recognition that traditional approaches to fire protection developed for terrestrial applications prove inadequate in the confined, potentially isolated environment of maritime installations. The International Electrotechnical Commission (IEC) has developed a comprehensive suite of standards specifically addressing these unique challenges.

IEC 60092-353 establishes the fundamental requirements for shipboard power cables, defining not only basic electrical performance parameters but also the environmental and safety characteristics essential for marine service. This standard recognizes that marine cables must perform reliably under conditions that would challenge or destroy conventional cables, including exposure to saltwater, extreme temperature variations, mechanical stress, and the ever-present risk of fire in confined spaces.

The flame spread characteristics of XLFMKK cables are verified through testing to IEC 60332-3-22, which evaluates the cable's ability to limit fire propagation when installed in bundles or cable trays. This test method simulates realistic installation conditions where multiple cables are installed in close proximity, creating the potential for fire to spread rapidly from cable to cable. XLFMKK cables demonstrate superior performance in these tests, with flame spread limited to minimal distances even under the most challenging test conditions.

Perhaps even more critical for marine safety is the cable's performance under IEC 60754-1 and IEC 60754-2 testing, which evaluates halogen acid gas emission during fire conditions. These tests measure both the quantity of halogen acid gases produced and their potential for causing corrosion to metal structures and electronic equipment. XLFMKK cables consistently demonstrate minimal halogen emissions, often below the detection limits of the test equipment, confirming their zero halogen construction.

The smoke density performance of XLFMKK cables, verified through IEC 61034 testing, proves equally impressive. This test method measures the optical density of smoke produced when cables are exposed to controlled fire conditions, simulating the visibility conditions that would exist during shipboard emergency evacuation. The low smoke characteristics of XLFMKK cables help maintain visibility in escape routes and enable emergency response personnel to locate and address fire sources more effectively.

These comprehensive fire safety characteristics provide multiple layers of protection in marine applications. The low smoke generation helps maintain visibility for evacuation and firefighting efforts, while the absence of toxic halogen gases reduces the risk of personnel exposure to life-threatening fumes. The minimal corrosive emissions also protect sensitive electronic equipment and structural components from fire-related damage that could compromise the vessel's safety systems.

The relevance of these fire safety characteristics becomes particularly apparent when we consider the enclosed nature of shipboard environments. Unlike terrestrial installations where natural ventilation and unlimited evacuation routes are typically available, marine installations must be designed with the understanding that personnel may be trapped in confined spaces with limited air circulation during emergency conditions.

Key Benefits in Marine and Offshore Installations

The unique combination of materials and construction techniques employed in XLFMKK cables delivers a comprehensive set of performance benefits that directly address the most challenging aspects of marine and offshore electrical installations. These benefits extend far beyond basic electrical functionality to encompass the environmental resilience, safety characteristics, and reliability requirements that distinguish marine applications from their terrestrial counterparts.

The fixed installation suitability of XLFMKK cables represents a fundamental advantage in marine applications where cable routing often involves complex pathways through bulkheads, around structural members, and through areas subject to regular cleaning and maintenance activities. The robust construction of these cables enables them to withstand the mechanical stresses associated with shipboard installation while maintaining their electrical and safety characteristics throughout their service life.

Oil and fuel resistance capabilities prove absolutely essential in marine environments where cables may be exposed to hydraulic fluids, diesel fuel, lubricating oils, and various cleaning solvents used in routine maintenance operations. The specialized sheath formulations used in XLFMKK cables maintain their integrity and protective characteristics even after prolonged exposure to these potentially degrading substances, preventing premature failure and maintaining safety performance.

The challenge of ultraviolet radiation and ozone exposure becomes particularly significant in marine applications where cables may be routed through areas exposed to intense sunlight reflected from water surfaces or installed on deck areas subject to direct solar radiation. The atmospheric ozone concentrations encountered in marine environments, particularly in tropical regions, can rapidly degrade conventional cable materials. XLFMKK cables incorporate UV-resistant and ozone-resistant compounds that maintain their mechanical and electrical properties even after years of exposure to these challenging environmental conditions.

Saltwater resistance represents perhaps the most distinctive environmental challenge in marine applications. The combination of salt spray, high humidity, and direct seawater contact creates conditions that can rapidly corrode metal components and degrade organic materials. The multiple protective layers incorporated in XLFMKK cable construction provide comprehensive protection against saltwater ingress while maintaining flexibility and mechanical strength under these corrosive conditions.

Mechanical stress resistance proves equally critical in marine installations where cables must withstand the constant flexing and vibration associated with wave action, engine operation, and structural movement. The cross-linked polyethylene insulation and robust sheath construction of XLFMKK cables maintain their integrity under these dynamic stress conditions, preventing the cracking and failure modes that commonly affect less robust cable designs.

The electromagnetic compatibility (EMC) shielding provided by the metallic screen layer addresses the increasingly complex electromagnetic environment found on modern vessels. Navigation radars, communication systems, variable frequency drives, and sophisticated control systems all generate electromagnetic fields that can interfere with sensitive electronic equipment. The comprehensive shielding provided by XLFMKK cables ensures clean power transmission while preventing both electromagnetic emissions from power cables and the ingress of external interference that could disrupt critical systems.

Long service life with minimal maintenance requirements represents a crucial economic advantage in marine applications where access for maintenance may be limited and replacement costs include not only material expenses but also significant labor costs and potential operational disruptions. The superior environmental resistance and robust construction of XLFMKK cables typically enable service lives measured in decades rather than years, providing exceptional value over the cable's operational lifetime.

Typical Applications of XLFMKK Cables

The versatility and robust performance characteristics of XLFMKK cables make them suitable for a wide range of marine and offshore applications, each presenting its own unique combination of environmental challenges and performance requirements. Understanding these typical applications helps marine engineers select the most appropriate cable specifications for their specific installation requirements.

Shipboard power distribution systems represent the most common application for XLFMKK cables, where they serve as the critical links connecting main switchboards to subsidiary distribution panels throughout the vessel. These applications require cables that can reliably carry substantial power loads while maintaining safety and electromagnetic compatibility in the confined spaces typical of shipboard installations. The robust construction and certified fire safety characteristics of XLFMKK cables make them particularly well-suited for these mission-critical applications.

In these power distribution roles, XLFMKK cables must often traverse multiple deck levels and bulkhead penetrations, requiring flexibility for installation while maintaining mechanical integrity under the dynamic stress conditions present on operating vessels. The cross-linked polyethylene insulation provides superior flexibility compared to thermoset alternatives while maintaining excellent electrical properties under varying temperature and humidity conditions.

Control circuits for marine equipment represent another significant application area where the electromagnetic compatibility characteristics of XLFMKK cables prove particularly valuable. Modern marine vessels incorporate sophisticated automation systems controlling everything from engine management to cargo handling equipment, and these control circuits must operate reliably in the electromagnetically noisy environment created by power electronics, radar systems, and communication equipment.

The metallic screening incorporated in XLFMKK cables provides effective protection against electromagnetic interference that could disrupt control signals or cause false actuations of critical equipment. This shielding capability proves especially important in applications involving variable frequency drives, where the switching frequencies and harmonic content can create significant electromagnetic emissions.

Offshore platforms and drilling rigs present some of the most challenging environments for electrical installations, combining the corrosive marine atmosphere with the additional hazards associated with hydrocarbon processing and drilling operations. XLFMKK cables have proven particularly successful in these demanding applications, where the combination of fire safety, environmental resistance, and electromagnetic compatibility proves essential for safe and reliable operations.

The fixed installation characteristics of XLFMKK cables make them well-suited for the permanent electrical infrastructure of offshore platforms, where cable replacement can be extremely difficult and expensive. The superior environmental resistance ensures reliable performance despite constant exposure to saltwater spray, while the flame retardant and low smoke characteristics provide additional safety margins in installations where hydrocarbon vapors may be present.

Port-side installations, including shore power connections, represent a growing application area for XLFMKK cables as the maritime industry increasingly focuses on reducing emissions while vessels are docked. These applications require cables that can withstand the mechanical stresses associated with frequent connection and disconnection while maintaining electrical integrity under varying weather conditions and potential exposure to dock-side contaminants.

The robust mechanical construction and environmental resistance of XLFMKK cables make them particularly suitable for these demanding applications, where cables may be subjected to physical handling, exposure to rain and snow, and potential contact with various dock-side chemicals and fuels. The electromagnetic compatibility characteristics also prove important in port environments where multiple vessels with different electrical systems may be operating in close proximity.

XLFMKK vs. Other Common Marine Cables

Understanding the relative advantages and limitations of different marine cable types enables engineers to make informed decisions about cable selection for specific applications. XLFMKK cables compete with several other specialized marine cable designs, each offering different combinations of performance characteristics and cost considerations.

FMKK cables represent a closely related alternative that shares many construction features with XLFMKK cables but utilizes different insulation technology. While FMKK cables offer similar fire safety and environmental resistance characteristics, the thermoplastic insulation used in these cables may not provide the same level of thermal stability and mechanical strength under extreme conditions that characterize XLPE insulation in XLFMKK cables.

The cross-linked polyethylene insulation in XLFMKK cables maintains its electrical and mechanical properties at higher temperatures than the thermoplastic alternatives used in FMKK cables, making XLFMKK the preferred choice for applications involving elevated ambient temperatures or where short-circuit performance is particularly critical. However, FMKK cables may offer cost advantages in applications where the superior high-temperature performance of XLPE insulation is not required.

RFOU cables represent another alternative commonly specified for marine applications, particularly in European installations. These cables incorporate rubber insulation and specialized sheathing compounds designed for marine environments, offering excellent flexibility and environmental resistance. However, the rubber insulation used in RFOU cables typically exhibits higher dielectric losses than the XLPE insulation found in XLFMKK cables, potentially making XLFMKK more suitable for applications involving longer cable runs or higher current densities.

The fire safety characteristics of RFOU cables may also differ from those of XLFMKK cables, depending on the specific rubber compounds and flame retardant additives used in their construction. While both cable types can meet marine fire safety standards, the inherent characteristics of LSZH compounds in XLFMKK cables may provide superior smoke and toxicity performance compared to some rubber-based alternatives.

BFOU cables, which incorporate mineral insulation systems, offer exceptional fire resistance and may be specified for the most critical marine applications. The mineral insulation used in these cables maintains its integrity even under direct flame exposure, providing unparalleled fire survival characteristics. However, the rigid nature and higher cost of mineral insulated cables limits their application to specific high-risk installations where their superior fire performance justifies the additional expense and installation complexity.

When comparing shielding effectiveness, XLFMKK cables typically provide more comprehensive electromagnetic compatibility protection than RFOU or BFOU alternatives, making them particularly suitable for installations where electromagnetic interference could affect sensitive electronic equipment or where electromagnetic emissions must be controlled to prevent interference with navigation or communication systems.

The decision of when to specify XLFMKK cables over other types depends on a careful evaluation of the specific application requirements, environmental conditions, and performance priorities. XLFMKK cables generally represent the optimal choice for applications requiring a combination of excellent fire safety, superior electromagnetic compatibility, robust environmental resistance, and reliable high-temperature performance.

Frequently Asked Questions

Marine engineers frequently encounter specific technical questions when evaluating XLFMKK cables for their projects. Addressing these common concerns helps ensure proper cable selection and installation practices that maximize the performance and safety benefits of these specialized cables.

Is XLFMKK suitable for outdoor marine use?

XLFMKK cables are specifically designed to excel in outdoor marine environments, incorporating UV-resistant and ozone-resistant sheath compounds that maintain their protective characteristics even after years of exposure to intense sunlight and atmospheric ozone. The multiple protective layers provide comprehensive protection against saltwater spray, while the robust mechanical construction withstands the dynamic stresses associated with shipboard installations. However, outdoor installations should still incorporate proper cable support and protection measures to maximize service life and maintain optimal performance.

Does it meet DNV, ABS, or Lloyd's Register type approval?

XLFMKK cables from reputable manufacturers typically carry type approvals from major classification societies including Det Norske Veritas (DNV), American Bureau of Shipping (ABS), and Lloyd's Register (LR). These approvals confirm that the cables meet the specific requirements established by these organizations for marine electrical installations. However, engineers should verify that the specific XLFMKK cable being considered carries the appropriate approvals for their project, as approval status can vary between manufacturers and specific product variants.

Can it be installed in cable trays or directly buried?

The versatile construction of XLFMKK cables makes them suitable for both cable tray installations and direct burial applications, though specific installation practices should be adapted to the chosen installation method. Cable tray installations benefit from the excellent fire safety characteristics and electromagnetic shielding provided by XLFMKK cables, while direct burial applications take advantage of the superior environmental resistance and mechanical strength. Proper installation practices, including appropriate bend radius control and mechanical protection where required, help ensure optimal performance in either installation configuration.

How does it perform under short-circuit conditions?

The cross-linked polyethylene insulation used in XLFMKK cables provides excellent short-circuit performance, with conductor temperatures up to 250°C permitted for brief periods during fault conditions. This superior thermal capability results from the thermoset characteristics of XLPE insulation, which maintains its structural integrity even at elevated temperatures that would cause thermoplastic insulation to soften or fail. The metallic screening also provides additional mechanical support during short-circuit conditions, helping maintain cable integrity during fault events.

What is the minimum bending radius and installation temperature?

XLFMKK cables typically require minimum bending radii of 6 to 8 times the cable diameter during installation, depending on the specific cable construction and manufacturer recommendations. Installation temperature ranges generally extend from -10°C to +50°C, though some formulations may permit installation at lower temperatures with appropriate precautions. These parameters ensure that the cable's mechanical and electrical characteristics are not compromised during installation while providing reasonable flexibility for routing through typical marine installation environments.

Conclusion: A Reliable, Certified Solution for Marine Engineers

The selection of appropriate cables for marine power systems represents one of the most critical decisions in shipboard and offshore electrical design, with implications extending far beyond basic electrical functionality to encompass safety, reliability, and operational economics. XLFMKK cables have emerged as a preferred solution for discerning marine engineers who refuse to compromise on performance, safety, or reliability.

The comprehensive approach to marine cable design embodied in XLFMKK construction addresses each of the fundamental challenges present in marine electrical installations. The cross-linked polyethylene insulation provides superior electrical performance and thermal stability, while the Low Smoke Zero Halogen sheathing ensures optimal fire safety characteristics in the confined spaces typical of shipboard installations. The electromagnetic compatibility shielding protects sensitive electronic systems from interference, while the robust environmental resistance ensures reliable operation under the harshest marine conditions.

The extensive certification and testing that validates XLFMKK cable performance provides marine engineers with documented assurance that these cables will perform as specified when subjected to the demanding conditions present in marine service. Compliance with international standards including IEC 60092-353, IEC 60332-3-22, IEC 60754-1/2, and IEC 61034 confirms that XLFMKK cables meet the most stringent requirements for marine electrical installations.

The proven track record of XLFMKK cables in demanding marine applications, from commercial shipping to offshore oil and gas installations, demonstrates their ability to deliver reliable performance under real-world conditions. The combination of superior environmental resistance, excellent fire safety characteristics, and comprehensive electromagnetic compatibility makes these cables particularly well-suited for the increasingly sophisticated electrical systems found on modern vessels and offshore platforms.

For shipbuilders, EPC contractors, and marine engineers seeking dependable low-voltage marine cable solutions, XLFMKK cables represent an investment in long-term reliability and safety. The initial cost premium associated with these high-performance cables is typically offset by their extended service life, minimal maintenance requirements, and superior safety characteristics that help protect both personnel and assets.

As marine electrical systems continue to evolve toward greater complexity and sophistication, the importance of selecting cables that can reliably support these advanced systems becomes even more critical. XLFMKK cables provide the proven performance foundation that enables marine engineers to design electrical systems with confidence, knowing that their cable infrastructure will provide reliable service throughout the vessel's operational life.

The future of marine electrical installations will undoubtedly bring new challenges and requirements, but the fundamental principles of safety, reliability, and environmental resistance that define XLFMKK cable design will remain as relevant as ever. For marine engineers committed to excellence in electrical system design, XLFMKK cables represent a trusted solution that delivers uncompromising performance when and where it matters most.